sealing conveyor BELTS

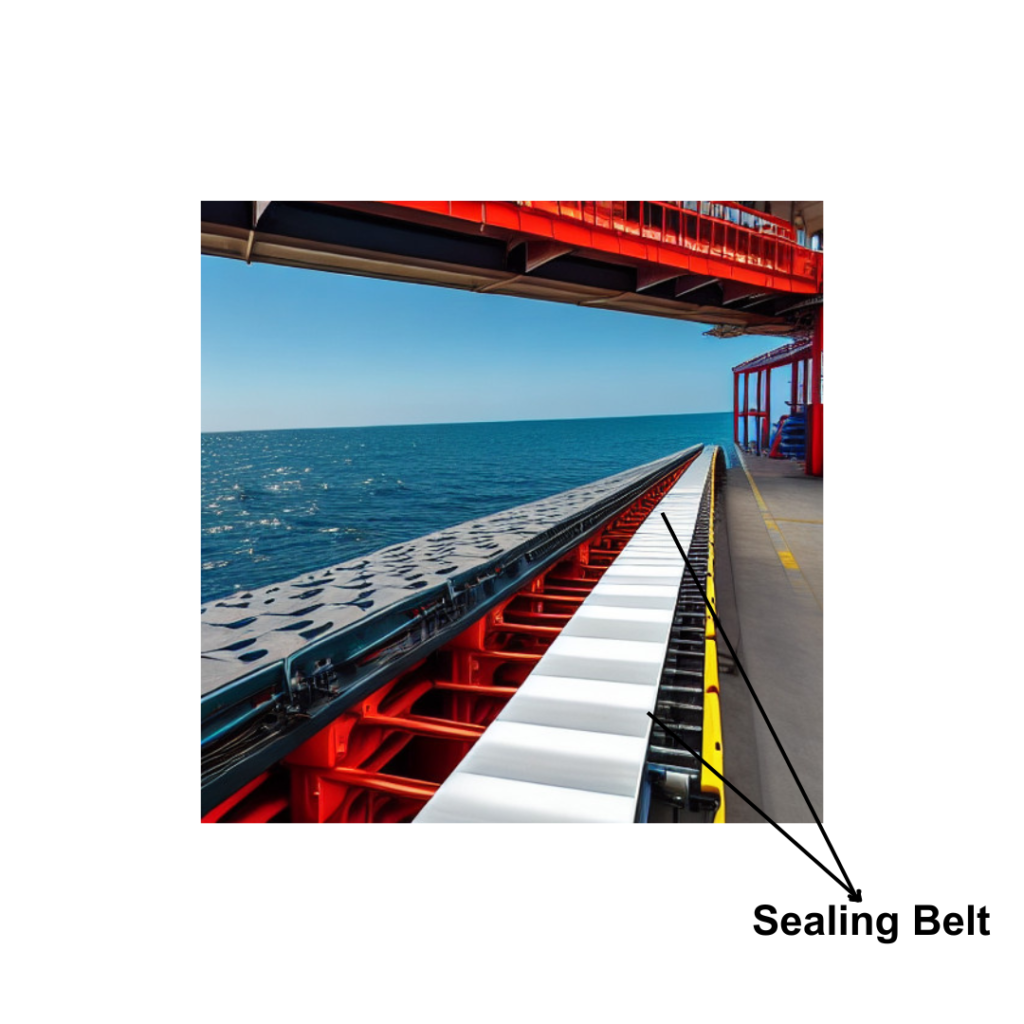

Bullflex Rubbers’ Sealing Conveyor Belts are highly durable and resistant to wear and tear, made with a variety of materials such as rubber, PVC, and other synthetic compounds. These belts are specifically designed to contain the material being transported within the conveyor system. They achieve this through specialized sealing systems that create a tight seal between the belt and the surrounding structure, such as gaskets, skirts, and other components. Bullflex Rubbers’ Sealing Conveyor Belts are suitable for transporting powders, granules, and liquids, and can be used in various conveyor systems, including belt conveyors, screw conveyors, and bucket elevators.

Product Application:

Sealing conveyor belts from Bullflex Rubbers are essential in various industries where the sealing of products is necessary. These belts are extensively used in industries such as packaging, pharmaceutical, chemical, agriculture, mining, and automotive industries. In the packaging industry, sealing conveyor belts help maintain the freshness and quality of food products. In the pharmaceutical industry, these belts help avoid contamination and maintain the integrity of drugs. Sealing conveyor belts are used in the chemical industry for sealing containers that contain hazardous chemicals, and in the agriculture industry, they are used for sealing bags of seeds, grains, and fertilizers. These belts ensure that there is no loss of valuable minerals during transportation in the mining industry. Lastly, in the automotive industry, sealing conveyor belts are used for sealing containers that contain automotive parts to maintain their quality and integrity during transportation. In summary, Bullflex’s sealing conveyor belts are critical in industries where products need to be transported safely without any contamination or spillage.

Product Characteristics:

| Common Widths : | 50 mm to 2600 mm |

| Carcass Variety Available : | EP / NN / EE / CC |

| Common Belt Rating : | 200 to 3150 kN/m |

| No. of Plies : | 1 ply to 7 ply |

| Rubber Cover Compounds : | Refer table for detailed properties |

| Rubber Cover Thickness : | 0.5 mm to 25 mm |

| Edge : | Cut/Moulded Edge |

| Splicing Method : | Hot/ Cold/ Mechanical |

| Belt Labelling : | Assigning distinct Product identification (Brand Name) to the product at every 6 meters. |