Steel Cord Conveyor Belts

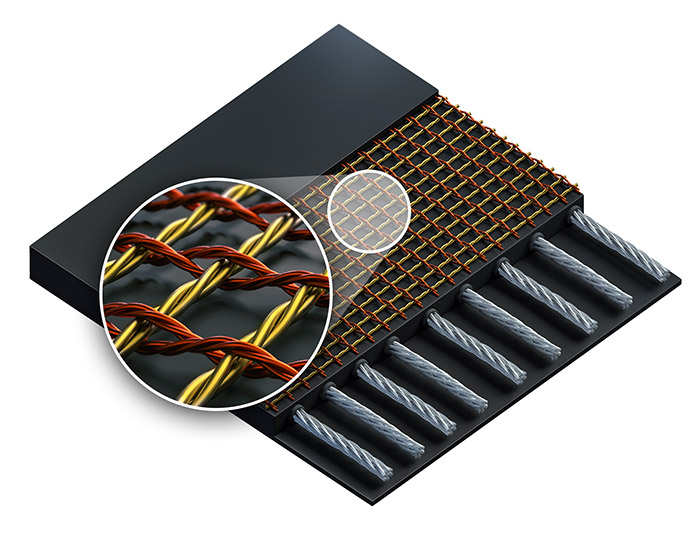

Steel Cord Conveyor Belts by Bullflex Rubbers are a type of heavy-duty conveyor belt that use steel cords as the reinforcing material. The steel cords are embedded in the rubber cover and core of the belt to provide high tensile strength and impact resistance. The belts are designed to handle the toughest conveying applications, including long distances, high speeds, and heavy loads. They are known for their durability, strength, and reliability. They offer a long service life and can handle heavy loads and harsh environments. They are also resistant to cutting, tearing, and abrasion, making them ideal for rugged applications. Additionally, their high strength-to-weight ratio allows for greater efficiency and lower operating costs.

Product Application:

Bullflex Rubbers’ Steel Cord Conveyor Belts are widely used in many industries due to their strength, durability, and high performance. The mining industry uses steel cord conveyor belts to transport coal, minerals, and other materials over long distances. The cement industry utilizes these belts to transport raw materials, finished products, and other materials used in the production process. Steel cord conveyor belts are also used in the steel industry to transport materials such as iron ore, steel, and scrap metal. In power plants, they are used to transport coal, ash, and other materials. Ports use steel cord conveyor belts to transport cargo such as containers, bulk goods, and other materials. Other applications include quarrying, recycling, agriculture, automotive industry, airport baggage handling, construction, and the packaging industry. Steel cord conveyor belts by Bullflex Rubbers are essential in various industries that require the transportation of heavy materials over long distances.

Product Characteristics:

| Common Widths : | 50 mm to 2600 mm |

| Carcass Variety Available : | EP / NN / EE / CC |

| Common Belt Rating : | 200 to 3150 kN/m |

| No. of Plies : | 1 ply to 7 ply |

| Rubber Cover Compounds : | Refer table for detailed properties |

| Rubber Cover Thickness : | 0.5 mm to 25 mm |

| Edge : | Cut/Moulded Edge |

| Splicing Method : | Hot/ Cold/ Mechanical |

| Belt Labelling : | Assigning distinct Product identification (Brand Name) to the product at every 6 meters. |